Our Products

WAMMCO offers global customers the entire range of chilled and frozen lamb, either as retail or food-service ready premium cuts, or whole carcase. We can also tailor products to suit any individual customer requirement. Our specialist teams can efficiently produce high-volume consignments of value-added products, all packaged and labelled to meet country-specific specifications.

We focus heavily on chilled products, with regular consignments of air and sea freight to markets in North America, the Middle East, Europe, Asia and Africa. Latest technology vacuum packing equipment helps guarantee maximum shelf-life, and our certified Quality Assurance programmes provide absolute confidence around the hygiene, safety and quality of our products upon arrival at their destination. We can supply the highest quality fresh lamb products twelve months of the year, and we are ideally placed to ensure reliable supply during high-consumption holiday periods including during Ramadan, Christmas and Easter.

WAMMCO International operates two Australian production sites (Plant Establishment Number = EST)

Technical Specifications

-

Specification:

Bone-In 4-5 Rib Square Cut Shoulder, Shank Off, Neck Off, Spinal Cord Removed.

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Bone In 4-5 Rib Lamb Forequarter, Shank, Neck and Breast On

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

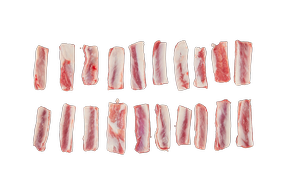

Specification:

Bone-in fore shank, removed from shoulder by straight bandsaw cut through base of arm bone, knuckle tip removed at rise of shank meat.

Packaging:

2 - 6 per Vacuum Pack or Layer Packed

-

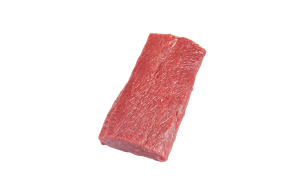

Specification:

Boneless Square Cut Shoulder

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped. Netted or flat packed

-

Specification:

Bone-in oyster cut shoulder, shank on, rib cage removed.

Packaging:

N/A

-

Specification:

Bone in Lamb Shoulder Rack is prepared from a square cut shoulder by the removal of the blade, cap, chine and feather bones leaving underlying muscles attached

Packaging:

2 Portions per vacuum pack

-

Specification:

Bone In Standard Rack Flap Removed Parallel with the Backbone and 75mm from Eye of the Loin

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Bone In Lamb CFO Rack Chine and Feather Bone Removed 75mm from the Eye of the Loin

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived from a CFO Rack and Frenched to a specified distance from the edge of the Eye of the Loin

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived from a CFO Rack and Frenched to a specified distance from the edge of the Eye of the Loin. Cap removed.

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived from a CFO Rack. Ribs to be cut to 40mm and Frenched back to eye muscle. Cap removed - Fully denuded

Packaging:

2 Racks per Vacuum bag

-

Specification:

Derived from a Full Loin with the Flap removed to the specified measurement from the eye muscle

Packaging:

1 per vacuum bag or Individually Wrapped

-

Specification:

Derived from a saddle by a cut through the M. Longissimus Thoracis between the 12th and 13th Ribs. Tail length to be specified

Packaging:

1 Portion Per Vacumm Pack or Individually Wrapped

-

Specification:

Derived from a Loin by a cut through the M. Longissimus Thoracis between the 12th and 13th Ribs

Packaging:

1 per vacuum bag or individually wrapped

-

Specification:

Derived from a Standard Shortloin Ventral Cutting line is 0mm and removal of the entire Fat Cap

Packaging:

2 per Vacuum Bag

-

Specification:

Prepared from a Shortloin by removal of the eye muscle portion. Silverskin removed

Packaging:

4 Portions per Vacuum bag

-

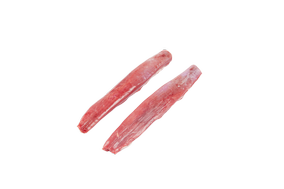

Specification:

Boneless Lamb Tenderloin - butt off

Packaging:

1kg Vacuum Bag

-

Specification:

Bone-In Leg, Shank On, Chump On, Aitch Bone In-Situ, Knuckle Tipped

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Chump is removed from a Leg Chump On by a cut approximately 12mm from the acetabulum at right angles across the primal

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived from a 4800 Leg with the removal of the Aitch Bone

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived From a 4800 Leg with the removal of the Aitch Bone and Chump

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived from an ABO Leg by removal of the Shank at the stifle joint

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived from an ABO Leg by removal of the Chump and the Shank at the stifle joint

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

The Hindshank is removed from the Leg by a cut through the stifle joint seperating the tibia and the femur. Tip removed

Packaging:

2 - 6 per Vacuum Pack or Layer Packed

-

Specification:

Derived from a Standard Leg C/On S/On (4800) by the removal of Bones, Cartlidge and tendons

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived from a Standard Leg C/On S/On (4800) by the removal of Bones, Cartlidge and tendons. Shank to be removed at the stiffle. Tunnel boned or Seam boned

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Derived by the removal of Bones, Cartlidge and Tendons. Shank to be removed at the stiffle. Chump to be removed. Tunnel boned or seam boned

Packaging:

1 Portion Per Vacuum Pack or Individually Wrapped

-

Specification:

Boneless Chump Cap On

Packaging:

Multivac Pack 2-8 Portions per Bag

-

Specification:

Boneless Chump Cap Off, Denuded

Packaging:

Multivac Pack 2-8 Portions per Bag

-

Specification:

Standard Whole Carcase Weight and Fat Score to be Specified

Packaging:

Poly Wrapped and Stockinetted

-

Specification:

Derived from a Whole Carcase Cut into Legs, Loins & Forequarters. 1 Leg, 1 Loin and 1 Forequarter packed into each carton

Packaging:

Layer Packed

-

Specification:

Derived from a Whole Carcase Cut into 6 portions 2 Legs, 2 Loins and 2 Forequarters

Packaging:

Layer Packed

-

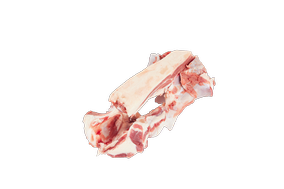

Specification:

Derived from a Boneless Leg and consists of both the Femur and Tibia Bones

Packaging:

Bulk Packed

-

Specification:

Derived from a Boneless Leg and consists of Femur Bones Only

Packaging:

Bulk Packed

-

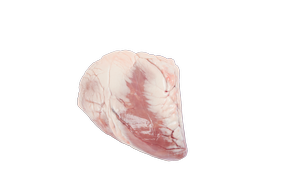

Specification:

Complete Heart with Blood Vessels removed by a straight cut at the base.

Packaging:

Bulk Packed or to Specification

-

Specification:

Prepared by removal from the capsule and removal of Blood vessels and the ureter at their point of entry to the kidney

Packaging:

1kg Bag or to Specification

-

Specification:

Complete Liver with removal of Fat, Blood Vessels, Gall Bladder and conective tissue. Lymph glands can remain in situ.

Packaging:

IW or Bulk Packed

-

Specification:

Thick skirt membrane trimmed back to mucle

Packaging:

Bulk Packed

-

Specification:

Well Scalded Whole Tripe

Packaging:

Layer Packed

-

Specification:

Derived from a Forequarter Pair by cutting along the dorsal line between the 3rd and 4th cervical vertebrae

Packaging:

Layer Packed

-

Specification:

Derived from a Loin or Saddle after a cut parallel to the Chine Bone at a specified distance from the eye muscle

Packaging:

Layer Packed

-

Specification:

Derived from a Rack/Shortloin after a cut parallel to the Chine Bone at a specified distance from the eye muscle

Packaging:

Layer Packed

-

Specification:

Derived from a Standard Square Cut shoulder with a Cut starting at the junction of the first rib and sternum, parallel with the Chine bone

Packaging:

Bulk Packed

-

Specification:

Lamb Rack Cap Consists of the Full Cap Covering the Eye Muscle along with the remaining Portion of the Scapular Cartlidge

Packaging:

Bulk Packed

-

Specification:

Derived from a Lamb Leg by a cut just below the Knuckle Joint and retaining the Tendon in Situ

Packaging:

Bulk Packed

-

Specification:

Full Chine Bone Derived by the removal from a rack

Packaging:

Bulk Packed

-

Specification:

Full Aitch Bone Derived from a Boneless Leg or ABO leg

Packaging:

Bulk Packed

-

Specification:

Derived by a straight cut across the pelvis

Packaging:

Bulk Packed

-

Specification:

Derived from the portion between the ribs during frenching

Packaging:

Bulk pack or Vacuum pack

-

Specification:

Saddle bone, remaining after removal of boneless loins

Packaging:

Bulk Packed

-

Specification:

Saddle bone, remaining after removal of boneless loins

Packaging:

Bulk Packed

-

Specification:

Contains the fat and meat remnants from ABO trim, shortloin cap, chump cap, shortloin trim

Packaging:

Bulk Packed

-

Specification:

Meat and fat remnants after preparation of primal cuts

Packaging:

Bulk Packed

Our Guarantee

Every WAMMCO International product comes with our assurance and absolute guarantee that it is:

Raised without

added hormones

Produced naturally

and minimally processed

Free from any type

of artificial ingredient

Certified under the LPA Livestock Production Assurance quality scheme

Processed by trained and competent staff employed by WAMMCO under government supervised programs at every step in the supply chain.

Products can be certified as, raised without antibiotics, grass fed, and pasture raised under WAMMCO’s specialist farm assurance programmes

Our Brands

West Coast Facility

West Coast Facility

The flagship brand of our West Australian production facility is ‘WAMMCO’. Strategically located in Katanning in Western Australia, supply for the brand is drawn from farmer-members in the Great Southern, the South Coast Region, the Eastern Wheatbelt and the Midwest region. Seafreight and airfreights are conducted via the ports of Fremantle and Perth Airport. WAMMCO produces a full range of high-quality lamb and mutton products under the fully trademarked WAMMCO brand, processing up to 30,000 lambs per week.

East Coast Facility

East Coast Facility

Our world-famous ‘FINE BRAND’ is synonymous with our east-coast production facility, Southern Meats. Located in Goulburn, NSW, Southern Meats utilises the prime production regions of the Southern Tablelands, the Riverina and the Central West. Exports are conducted via the port of Sydney. Southern Meats produces a full range of high-quality lamb and mutton products. Latest technology facilities cater for efficient production of up to 30,000 head of lamb and mutton per week, along with associated skins, offals and by-products.

Australia-wide production facilities provide WAMMCO with

Large-scale operations to service major retail and food service customer accounts.

Protects against business and biosecurity risk with operations in geographically separate livestock and production regions.

Competitive shipping services from Katanning, Fremantle, Goulburn and Sydney.

All WAMMCO International livestock is accompanied by a valid National Vendor Declaration (NVD) which describes livestock ownership which allows full traceability back to the producer and/or place of origin.

All WAMMCO carcases and cartons are labelled in accordance with AUS Meat (Authority for Uniform Specification – Meat) labelling requirements, providing further assurance for full product traceability.

Accreditations

With a focus on producing the finest eating lamb and mutton products, and a strong quality assurance framework in place, WAMMCO boasts a suite of accreditations for our products, giving our membership and our valued customers surety and certainty that WAMMCO products are the best available on the market, anywhere in the world.

Our accreditations include:

Animal welfare certification

USDA approved

A+ Ausmeat accreditation

BRC level AA

Halal Certified

HACCP

Market accreditation includes:

USA/Canada

EU/UK

China

Japan/Korea

Malaysia

Indonesia

Middle East

all other major markets

Policies and Compliance

2023 – 2024 Public Questionnaire

2023 – 2024 Workforce Statistics – Public Report

2023 – 2024 Workplace Profile – Public Report

Employment Provider Policy

Social Compliance Policy – WAMMCO

Certifications

AUSMEAT North American Audit Criteria – WAMMCO

AUSMEAT Animal Welfare – WAMMCO

BRC Global Standard For Food Safety – WAMMCO

ICCV Halal Certificate – WAMMCO

Certificate of Accreditation – WAMMCO

AUSMEAT North American Audit Criteria – Southern Meats

ICCV Halal Certificate – Southern Meats

AUSMEAT Animal Welfare – Southern Meats

BRC Global Standard For Food Safety – Southern Meats

Quality Assurance

The application of our rigorous WAMMCO quality assurance framework begins on-farm, with regular information updates and consultation direct with farmers to support and encourage the growth and supply of top-quality lean carcase livestock.

This includes information about flock management, animal welfare, breed performance, preferred carcase type and current marketing opportunities. Detailed post-slaughter data is also provided to farmers as a measure of livestock lot performance.

Prior to the sale of livestock, all suppliers are required to submit a Vendor Declaration confirming that all livestock conform to WAMMCO International’s stringent export requirements. This declaration provides confirmation that livestock have never been fed any product containing or made from animal protein materials.

All WAMMCO International abattoir activities are conducted strictly under an integrated quality assurance program, incorporating all elements of the MSQA (Meat Safety Quality Assurance) program together with a comprehensive HACCP (Hazard Analysis Critical Control Point) food hygiene program.

This includes regular inspection, testing and auditing by independent sources such as the Department of Agriculture, Fisheries and Forestry. It also includes micro-testing of product/production environments, conformance to prescribed animal welfare instructions and strict adherence to customer and product specifications.

WAMMCO facilities adhere to world-class quality assurance systems including A+ AusMeat Accreditation, BRC (British Retail Consortium) Global Standard for Food Safety and MSQA.

In addition to these standards and quality assurance requirements, metal detection facilities screen all products after carton sealing as a further control/assurance measure. Programs ensuring transparency and traceability of livestock products back to the farm gate are an important part of WAMMCO International’s QA program.

WAMMCO International products are produced and exported along an unbroken cold-chain, comprising temperature-controlled loading environments at every step of the supply chain process to ensure the highest quality, food safety and extended shelf life.